PARTENAIRES

INDUSTRIE SUISSE

Conçus et fabriqués en Suisse, nos concepts Flatmatic® et Openmatic® illustrent la précision et l’innovation des lunettes IKYUM®. Découvrez le savoir-faire de nos partenaires industriels qui donnent vie à ces designs avec une qualité et un artisanat exceptionnels.

TITANE DE QUALITÉ 5

TECHNOCUT

Notre partenaire TECHNOCUT SA basé à Bonfol en Suisse, réputé pour sa découpe laser de précision, est à la pointe de la technologie. Ils fabriquent méticuleusement nos branches de lunettes Flatmatic en titane grade 5 à l'aide de techniques laser avancées. Leur savoir-faire exceptionnel garantit une qualité et une précision inégalées dans chaque pièce, donnant vie à notre vision de lunettes innovantes.

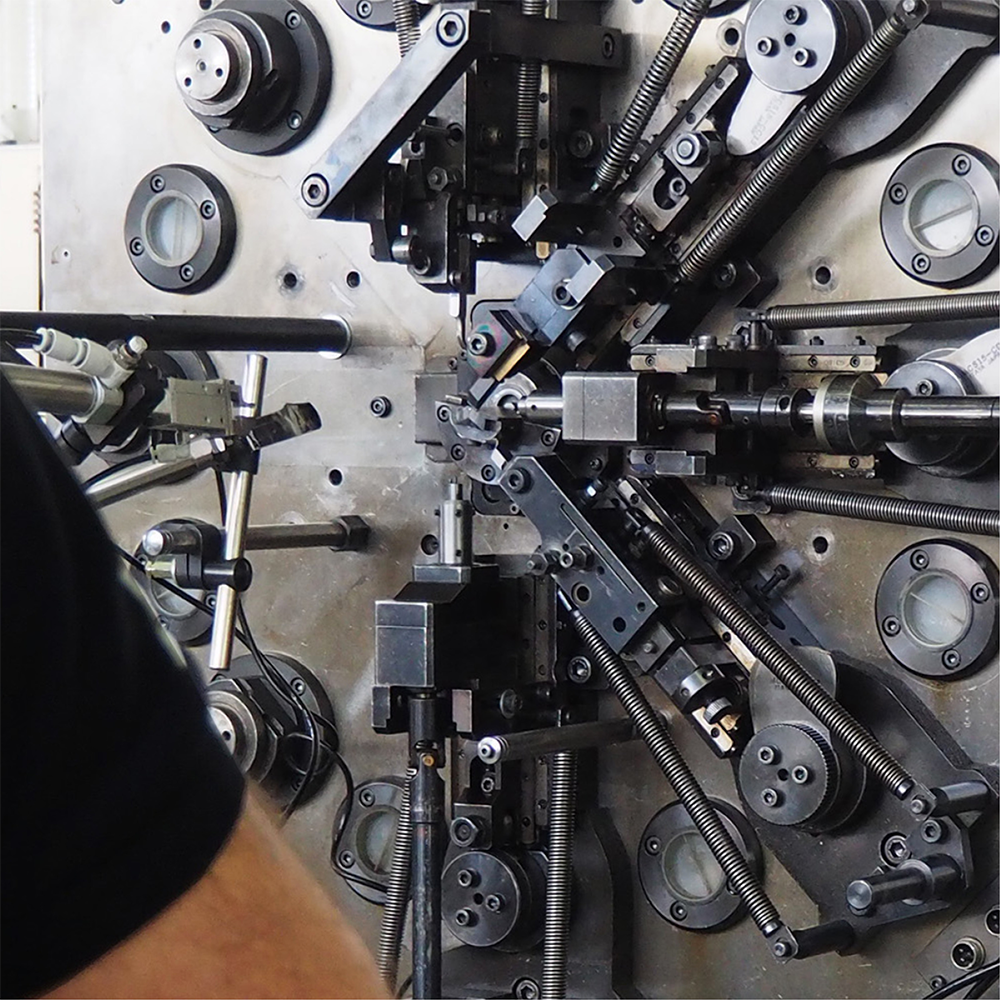

RESSORTS PLIÉS

SORED

SORED SA , entreprise avec près d'un siècle de tradition et d'expertise dans la production de pièces embouties et pliées et de ressorts en fil, s'est imposée comme un leader du marché. Ils fabriquent les charnières de nos châssis OPENMATIC, offrant des mécanismes fiables et durables.

DOUX AU TOUCHER

MICROFINITION

MICROFINISH SA basée à Villeneuve en Suisse, forte de plus de 50 ans d'expérience, est devenue leader dans le traitement de surface par impact. En tant que leader suisse de la finition de pièces de précision, ils ont gagné la confiance des secteurs de l'horlogerie, du médical, de la connectique et de l'automobile depuis plus de cinq décennies. Ils assurent la finition de nos branches FLATMATIC®, garantissant une qualité irréprochable à nos composants de lunettes de précision.